Co-extruded WPC decking represents a significant advancement in the world of wood-plastic composite materials, offering a solution that combines the best attributes of both wood and plastic with added innovations. This second-generation WPC decking is known for its enhanced durability, aesthetic appeal, and maintenance ease. Here are the key features that set co-extruded WPC decking apart:

Enhanced Durability and Longevity

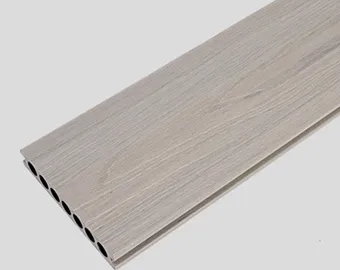

Co-extruded WPC decking is manufactured through a process that covers the core of the decking with a layer of harder, more durable material. This outer layer, typically made from a denser, more wear-resistant plastic, shields the decking from the elements. It significantly improves the deck’s resistance to moisture, decay, fading, and scratching, contributing to a longer service life compared to first-generation WPC decking.

Superior Weather Resistance

The protective outer layer of co-extruded WPC decking is engineered to withstand harsh weather conditions, including intense sunlight, rain, snow, and temperature fluctuations. This makes co-extruded WPC decking an ideal choice for outdoor applications in various climates, ensuring that the deck maintains its color and integrity over time.

Low Maintenance Requirements

One of the most appealing features of co-extruded WPC decking is its low maintenance. Unlike traditional wood decking, which requires regular staining, sealing, or painting to maintain its appearance and durability, co-extruded WPC decking needs only basic cleaning. The protective layer prevents staining and mold growth, making upkeep a breeze.

Aesthetic Appeal

Co-extruded WPC decking offers a wide range of colors, textures, and finishes, allowing for greater customization to match any outdoor design aesthetic. The outer layer can be designed to mimic the look and feel of natural wood closely, providing the beauty of wood without the associated maintenance. The consistency of color and texture across the decking adds to its visual appeal.

Eco-Friendly

Like other WPC products, co-extruded WPC decking is made from a blend of recycled wood fibers and plastics, making it an environmentally friendly choice. The production process reduces waste by repurposing materials that would otherwise end up in landfills, contributing to a more sustainable construction option.

Improved Safety

The surface of co-extruded WPC decking can be engineered to provide better slip resistance than traditional wood or first-generation WPC decking. This makes it a safer option for areas that are frequently wet, such as pool surrounds or outdoor showers.

Versatility in Application

Due to its durability, aesthetic flexibility, and resistance to the elements, co-extruded WPC decking is suitable for a wide range of outdoor applications. From residential decking to commercial spaces, it can accommodate various design needs and functional requirements.

In summary, co-extruded WPC decking offers a compelling combination of durability, aesthetic appeal, low maintenance, and environmental sustainability. Its advanced manufacturing process and protective outer layer make it a superior choice for anyone looking to invest in long-lasting, beautiful outdoor flooring.