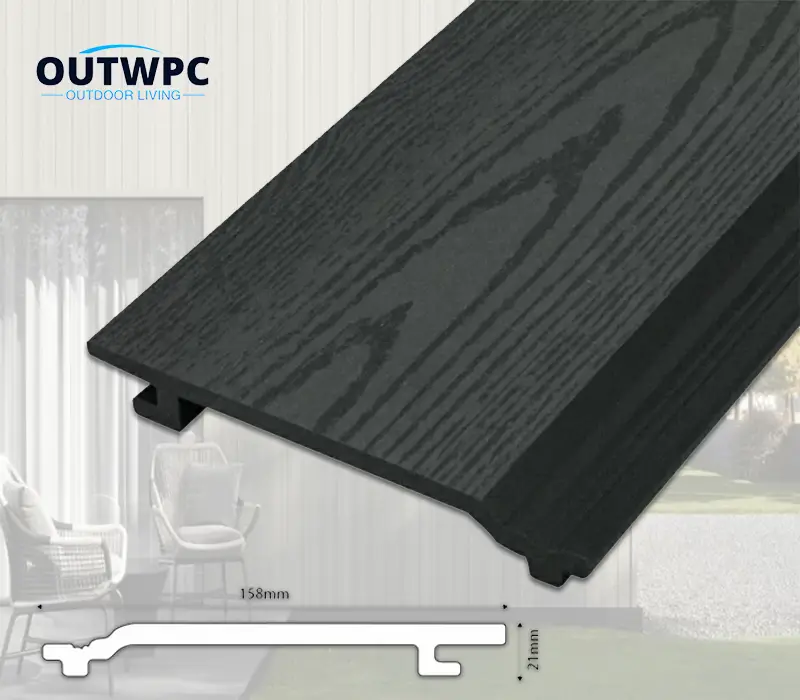

OUTWall

Second generation exterior WPC wall cladding

As the demand for eco-friendly and durable building materials continues to rise, the second generation of exterior WPC wall cladding emerges as a revolutionary solution. Building upon the success of its predecessor, these advanced co-extruded wall panels from OUTWPC offer a host of enhanced features and benefits, making them the preferred choice for modern construction projects.

Second generation exterior WPC wall cladding

Home > Product > Exterior Wall Panel > WPC Cladding > Second generation

Second-generation wood-plastic exterior wall cladding represents a major advance in building materials technology. Focused on environmental health, durability, fire safety and insect resistance, these coextruded panels from OUTWPC provide builders and occupants with unparalleled performance and peace of mind. Whether for residential, commercial or industrial applications, second generation WPC exterior cladding sets new standards for excellence in modern construction.

- Manufacturer: OUTWPC

- Product name: OUTWall

- Style name: Second generation WPC Fluted Panel

- Product material: wood powder, PE, etc.

- Product size: 146X21mm, customization .

- Product length: Normally 3 meters, customization is available.

Environmental health

OUTWPC’s second-generation co-extruded wall panels are extruded from natural wood powder and ten polymers + resin. They have passed national quality inspection.

Paint-free, waterproof

OUTWPC co-extruded wall cladding uses a polymer anti-corrosion organic formula to effectively solve the wood’s fear of water, rot and other characteristics.

Strong flame retardant properties

The co-extruded WPC wall panel has passed the Chinese National Building Materials Test and its combustion performance level has reached the B1 flame retardant level.

FSC polymer insect repellent

The co-extruded WPC wall cladding uses raw wood fiber and adds FSC polymer to optimize the wood fiber structure, making it no longer a delicacy in the eyes of insects and achieving an insect-proof effect.

The Evolution of Exterior WPC Wall Cladding: Second Generation Innovations

In addition to environmental and safety considerations, second-generation co-extruded WPC wall cladding offers advanced insect repellent properties. By incorporating FSC polymer into the raw wood fiber structure, these panels effectively deter insects and pests, ensuring long-term durability and preservation of the building exterior. This innovative feature eliminates the need for chemical insecticides and promotes sustainable pest management practices.

Environmental Health:

OUTWPC’s second-generation exterior wall panels prioritize environmental health and safety. Crafted from natural wood powder and a blend of ten polymers + resin, these panels undergo rigorous quality inspections to ensure low formaldehyde emissions and compliance with environmental protection standards. Achieving the E0 level certification, these panels provide peace of mind to environmentally conscious builders and occupants alike.

Paint-Free, Waterproof:

One of the standout features of second-generation co-extruded wall cladding is its paint-free, waterproof, and highly durable nature. Utilizing a polymer anti-corrosion organic formula, these panels effectively combat water damage, rot, and other environmental stressors without the need for painting or additional coatings. This exceptional durability ensures longevity and performance in even the most extreme environments, making it an ideal choice for outdoor applications.

Strong Flame Retardant Properties:

Safety is paramount in building design, and second-generation co-extruded exterior WPC wall panels deliver on this front with strong flame retardant properties. Having passed rigorous testing by the Chinese National Building Materials Test, these panels achieve a B1 flame retardant level, providing added protection against fire hazards and enhancing overall building safety.

Mounting Accessories