OUTWall

First generation exterior WPC wall cladding

In the ever-evolving world of real estate, aesthetics, and quality play pivotal roles in attracting potential buyers. As the market becomes increasingly discerning, developers are turning to innovative materials like wood plastic composite (WPC) wall cladding to enhance the appeal and value of their properties. Here’s why exterior WPC wall cladding is becoming the preferred choice for modern estate projects:

First generation exterior WPC wall cladding

Home > Product > Exterior Wall Panel > WPC Cladding > First generation

Exterior WPC wall cladding adds a touch of elegance and sophistication to any property. With its natural wood grain texture and rich colors, it exudes warmth and charm, creating an inviting ambiance that resonates with discerning buyers. Whether used in residential or commercial settings, WPC wall cladding elevates the visual appeal of buildings, making them more attractive to potential buyers.

- Manufacturer: OUTWPC

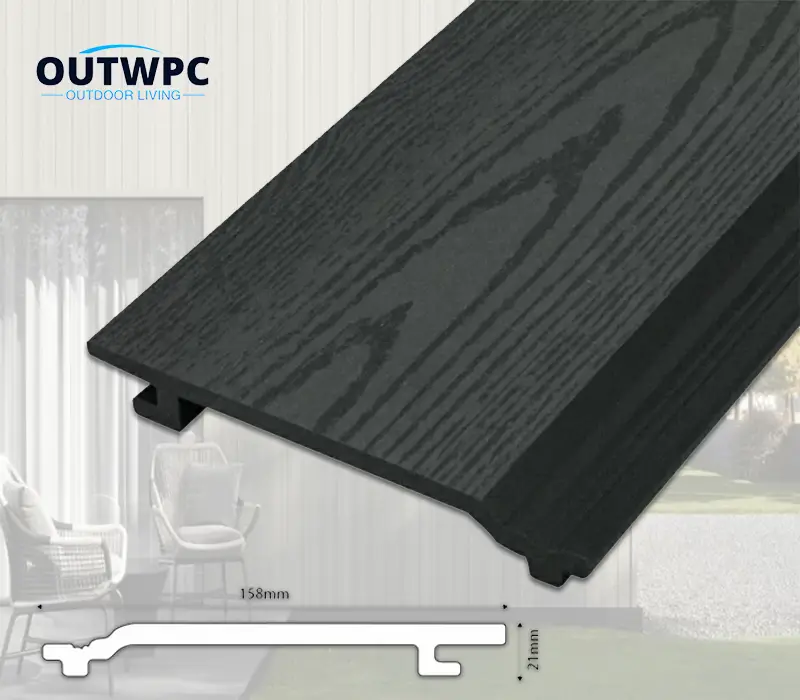

- Product name: OUTWall

- Style name: First generation WPC Cladding

- Product material: wood powder, PE, etc.

- Product size: 146X21mm, customization .

- Product length: Normally 3 meters, customization is available.

Clear texture

Imitate the texture of natural wood to improve the beauty of your house.

Corrosion resistance

Easily withstand the erosion of harsh environments.

Strong plasticity

The product quality is hard, the surface is smooth and flat, and the wear resistance is good.

Waterproof and moisture-proof

It solves the problem that wooden products are prone to decay when exposed to moisture in streams in humid environments.

The Advantages of Exterior WPC Wall Cladding in Real Estate

In today’s environmentally conscious society, sustainability is a key consideration for real estate developers. WPC wall cladding is an eco-friendly alternative to traditional building materials, as it is made from a combination of recycled plastic, natural fibers, and additives. By using WPC wall cladding, developers can reduce their carbon footprint and contribute to a greener future, while still delivering high-quality, aesthetically pleasing properties.

Exterior WPC wall cladding is designed for easy installation, making it a preferred choice for contractors and developers. Its lightweight nature and carpenter-friendly design allow for quick and hassle-free installation, saving both time and labor costs. Additionally, WPC wall panel is available in structural product options, providing versatility and flexibility in design and construction.

Unlike traditional building materials that require regular painting, staining, and maintenance, WPC exterior wall cladding is virtually maintenance-free. Its UV-resistant finish prevents fading and discoloration over time, while its dimensional stability ensures that it maintains its shape and appearance in any climate. With minimal upkeep required, outdoor WPC cladding offers convenience and peace of mind to property owners and developers alike.

WPC wall board offers superior durability and longevity compared to wood and plastic alternatives. Its unique composition makes it resistant to cracking, warping, and splitting, ensuring that the building exterior remains pristine for years to come. Additionally, WPC wall exterior panel is impervious to water, moisture, pests, and harsh environmental conditions, making it an ideal choice for both indoor and outdoor applications.

Mounting Accessories

WPC Wall Panel - WPC Wall Board

First generation exterior WPC wall cladding

Data sheet | |||

PRODUCT SPECIFICATION | |||

Item | Standard | Requirements | Result |

Slip Resistance Dry | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 EN 15534-4:2014 Section 4.4 | Pendulum value≥36 | Longtitudinal direction:Mean 72,Min 70 Horizontal direction:Mean 79,Min 78 |

Slip Resistance Wet | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 EN 15534-4:2014 Section 4.4 | Pendulum value≥36 | Longtitudinal direction:Mean 46,Min 44 Horizontal direction:Mean 55,Min 53 |

Falling mass impact resistance | EN 15534-1:2014 Section7.1.2.1 EN 15534-4:2014 Section 4.5.1 | None of the speciments shall a failure with a crack length≥10mm or a depth of residual indentation≥0.5mm | Max.Crack length(mm):No crack Max.Residual indenation(mm):0.31 |

Flexural properties | EN15534-1:2014 AnnexA EN 15534-4:2014 Section 4.5.2 | -F’max:Mean≥3300N,Min≥3000N -Deflection under a load of 500N Mean≤2.0mm,Max≤2.5mm | Bending Strength:27.4 MPa Modulus of elasiticity:3969 MPa Maximum load: Mean 3786N,Min 3540N Deflection at 500N: Mean:0.86mm,Max:0.99mm |

Creep behaviour | EN 15534-1:2014 Section7.4.1 EN 15534-4:2014 Section 4.5.3 | Known span in use: Mean ∆S≤10mm,Max ∆S≤13mm, Mean ∆Sr≤5mm | Span: 330mm,Mean ∆S 1.65mm,Max ∆S 1.72mm,Mean ∆Sr 1.27mm |

Swelling and water absorption | EN 15534-1:2014 Section8.3.1 EN 15534-4:2014 Section 4.5.5 | Mean Swelling:≤4% in thickness,≤0.8% in width,≤0.4% in length Max swelling:≤5% in thickness, ≤1.2% in width,≤0.6% in length Water absorption:Mean:≤7%,Max:≤9% | Mean Swelling:1.81% in thickness,0.22% in width,0.36% in length Max Swelling:2.36% in thickness,0.23% in width,0.44% in length Water absorption:Mean:4.32%,Max:5.06% |

Boiling Test | EN 15534-1:2014 Section8.3.3 EN 15534-4:2014 Section 4.5.5 | Water absorption in weight: Mean≤7%,Max≤9% | Water absorption in weight: Mean:3.06%,Max:3.34% |

Linear thermal expansion coefficient | EN 15534-1:2014 Section9.2 EN 15534-4:2014 Section 4.5.6 ISO 11359-2:1999 | ≤50×10⁻⁶ K⁻¹ | 34.2 x10⁻⁶ K⁻¹ |

Resistance to indentation | EN 15534-1:2014 Section7.5 EN 15534-4:2014 Section 4.5.7 | Brinell hardness: 79 MPa Rate of elastic recovery:65% | |

Heat reversion | EN 15534-1:2014 Section9.3 EN 15534-4:2014 Section 4.5.7 EN 479:2018 | Test Temperature:100℃ Mean: 0.09% | |